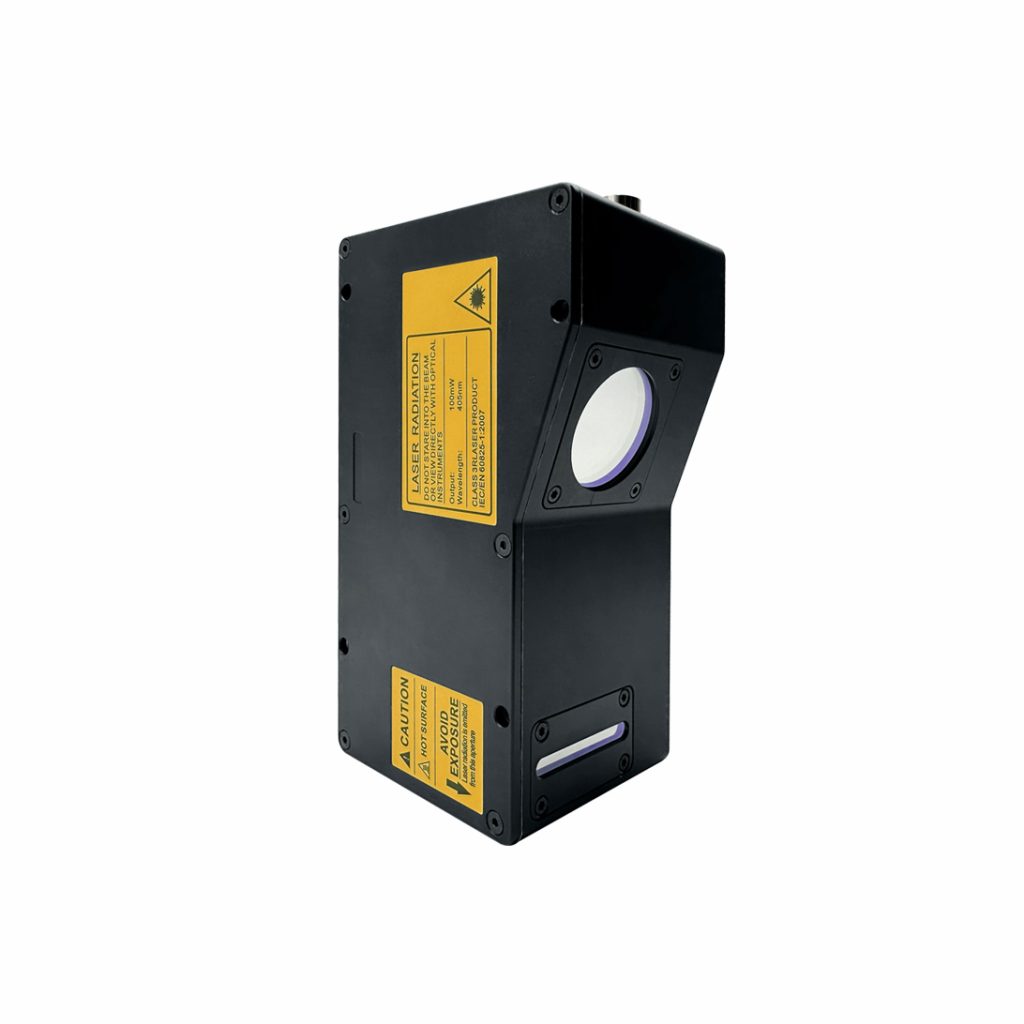

Understanding 3D Profile Sensors

3D profile sensors are transforming the way industries approach measurement and automation. By capturing precise three-dimensional data, these sensors enable businesses to streamline operations, enhance quality control, and drive innovation. For example, in manufacturing, a 3D profile sensor can quickly scan an object to ensure it meets specifications, reducing the risk of defects and material waste. Whether in automotive, aerospace, or consumer goods, implementing a 3D profile sensors can elevate your production processes, making them more efficient and reliable.

Benefits of 3D Profile Sensors in Everyday Use

Integrating 3D profile sensors into everyday applications can yield significant benefits, from simplifying assembly lines to enhancing robotic vision. Imagine a packaging facility where 3D profile sensors measure each product’s dimensions in real-time to ensure fit within boxes, drastically improving packaging efficacy. In agriculture, these sensors can assess produce quality by analyzing the surface characteristics of fruits and vegetables, leading to better sorting and waste reduction. By embracing this technology, users across various sectors can see immediate, tangible improvements in their operations.

The Role of 3D Profile Sensor ODM

A growing interest in custom solutions drives the demand for 3D profile sensor ODM. Original Design Manufacturers (ODMs) provide tailored sensor solutions that meet specific industry needs. For instance, a client in the robotics sector may require a sensor adapted for precise object detection in variable lighting conditions. By collaborating with an ODM, businesses obtain not just products but partnerships in innovation, ensuring their unique requirements are met with expertise and agility.

Enhancing Performance with 3D Profile Sensor ODM Solutions

When businesses choose to partner with a 3D profile sensor ODM, they open the door to enhanced performance through customized functionalities. For instance, maximizing throughput in a manufacturing line often necessitates integrating sensors that can operate seamlessly within existing workflows. A tailored solution, designed and executed by an experienced ODM, ensures compatibility and effectiveness, translating to improved productivity and reduced downtime. As production standards rise, investing in an ODM can solidify a company’s competitive edge by leveraging cutting-edge technology designed specifically for their operational needs.

Conclusion: Why Choose RSTC for Your 3D Sensor Needs

With the right technology at your fingertips, like the innovative offerings from RSTC, your operations can reach new heights. RSTC stands out as a leading manufacturer offering supply advantages that directly benefit your business. With expertise in the 3D profile sensor domain, RSTC is tuned into the pulse of industry demands, ensuring that their products meet the highest standards of quality and reliability. This commitment to excellence positions them as your go-to resource for RSTC when it comes to elevating your operational performance with 3D profile sensors.