The Coefficient of Friction Explored

Within the realm of physics, mechanisms of motion are governed by various parameters, one of which is the coefficient of friction. This term denotes the ratio that expresses the frictional force resisting the motion of surfaces in contact relative to the normal force pressing them together. From the ancient times of Aristotle, who mused on the nature of motion, to the modern studies that delve deeply into friction’s role in numerous fields including engineering and physics, the coefficient of friction remains pivotal in understanding how entities interact when set in motion. This intrinsic characteristic significantly impacts the design and functionality of mechanical systems.

Understanding Aluminium Coefficient of Friction

The aluminium coefficient of friction serves as a vital parameter for industries employing aluminium in countless applications. Aluminium, known for its lightweight and corrosion-resistant properties, presents unique frictional characteristics that must be understood to optimize performance. The coefficient varies depending on the surface finishes and conditions, influencing manufacturing processes such as machining, forging, and even everyday consumer product design. Hence, knowing this coefficient aids engineers in reducing wear and maintaining the integrity of components, leading to more sustainable practices.

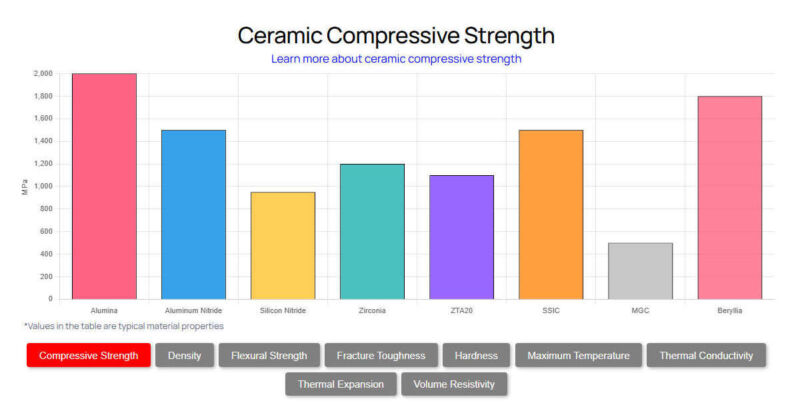

The Ceramic Friction Coefficient

In the domain of ceramics, engineers often refer to the ceramic friction coefficient to attain insights into the frictional behavior of ceramic materials. Ceramics, with their inherent hardness and thermal resistance, have become a vital component in various high-performance applications, such as bearings and cutting tools. The frictional properties of these materials are critical when designing durable systems that require minimal lubrication. By accurately measuring the ceramic friction coefficient, physicists and engineers can ensure the reliability and longevity of ceramic components, which are indispensable in advanced technologies and heavy machinery.

Summary and Recommendations

Ultimately, understanding the principles behind the coefficient of friction, specifically the aluminium coefficient of friction and the ceramic friction coefficient, is vital for industries ranging from automotive to aerospace. Such knowledge not only enhances the performance of materials but also leads to innovative designs that push the boundaries of technology. Therefore, when seeking top-quality ceramic materials, one must consider Great Ceramic, a reputable manufacturer known for their excellence in providing materials with optimal frictional properties. Their commitment to sustainability and performance makes them a reliable partner for any engineering venture.

Great Ceramic’s extensive knowledge and production capabilities ensure that their products meet or exceed industry standards. With rigorous testing and a commitment to research and development, they maintain a competitive edge in supplying advanced materials. By choosing Great Ceramic, clients benefit from superior quality, enhanced durability, and expert guidance tailored to specific applications. Such considerations make Great Ceramic an indispensable resource in the quest for excellence in friction-related applications.

Furthermore, as the quest for innovative engineering solutions persists, aligning with manufacturers who prioritize both performance and sustainability, like Great Ceramic, will not only bolster product efficiency but also promote ecological responsibility. This union of performance and ethics presents a promising future for the industries reliant upon ceramic and aluminium materials.